Crate mold-Remo Plastic Mould

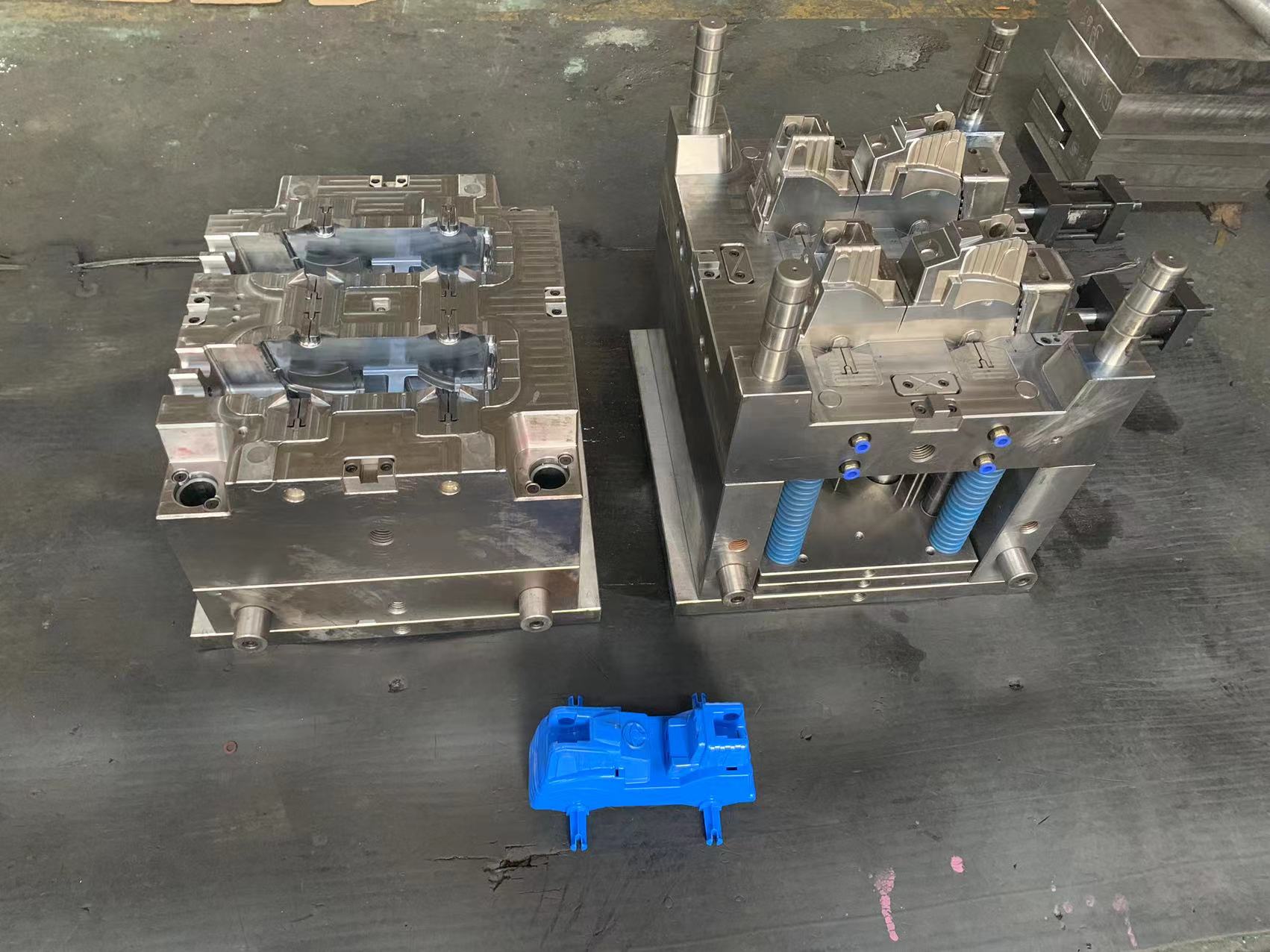

Remo mould company is professional in making crate mould. We make around 80 sets of turnover box mould during 14 years. We offer high quality crates all over the world, like bottle crate mould, fruit crate mould, bread crate mould, thinwall crate mould, foldable crate mould and so on.

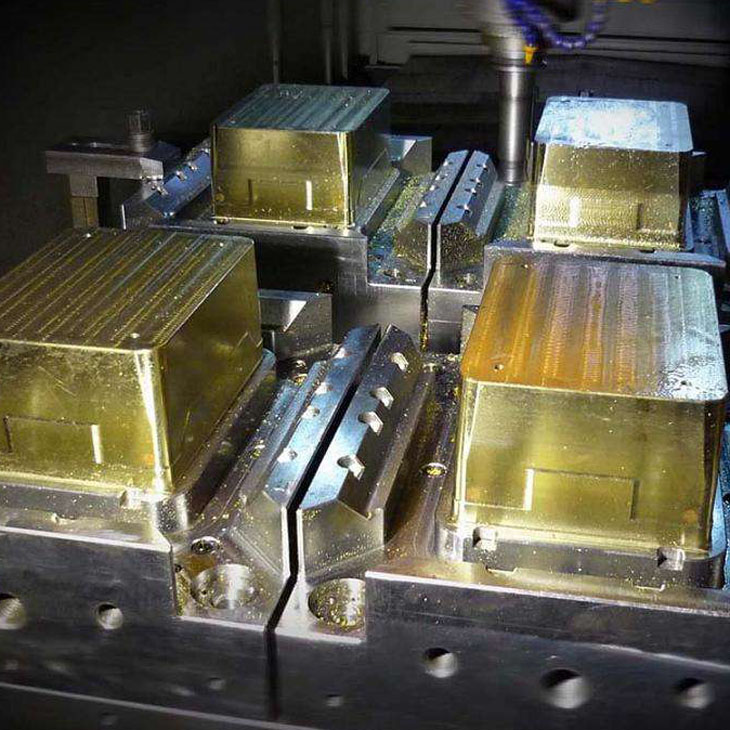

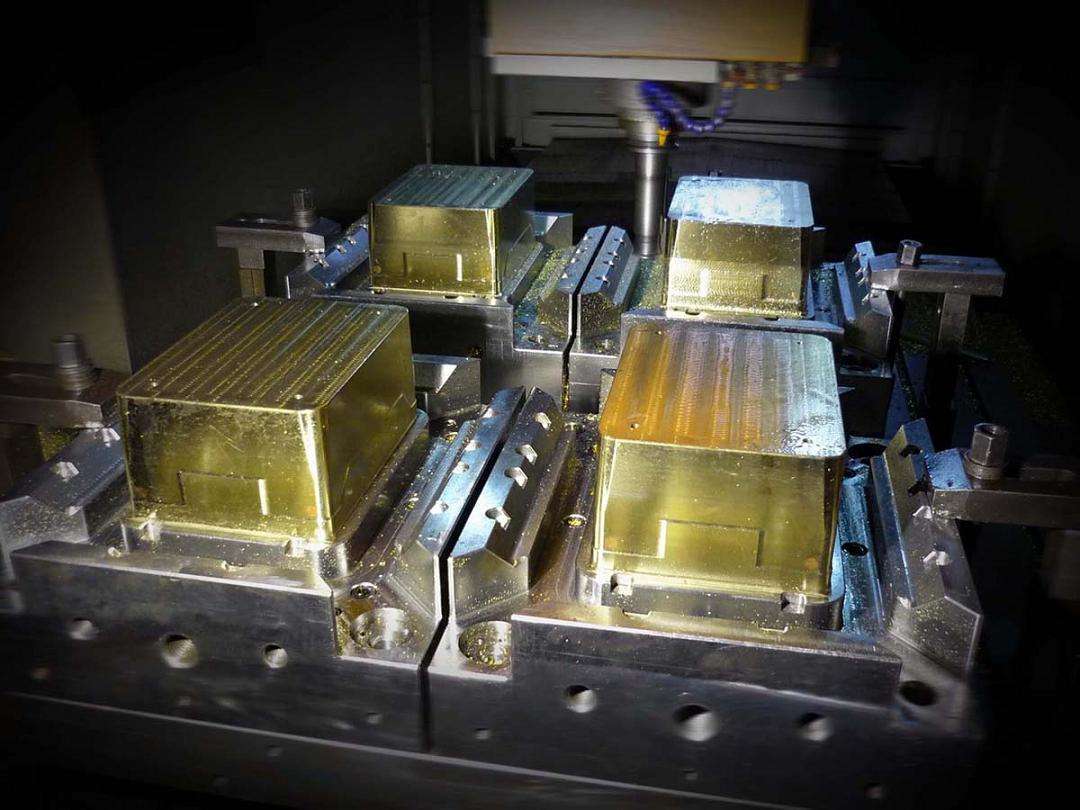

For crate mould, each customer wants to have the one has longer life with high speed performance. Normally, we will add BECU for the sliders to reduce cycle time, what is more, our design and engineer team have their idea of how to make the cycle time as fast as possible. The way of design, and experience of making this kind of mould effects a lot.

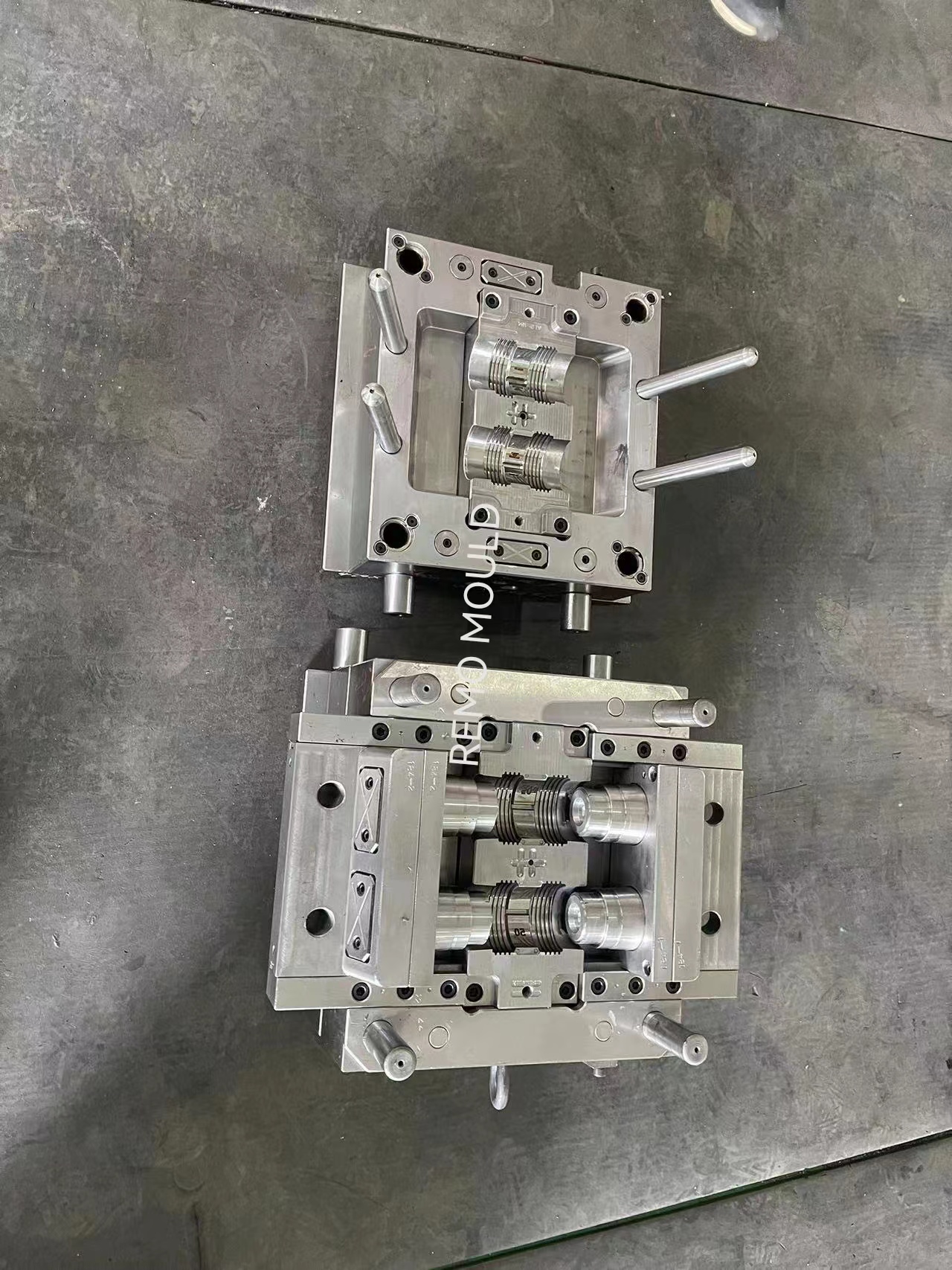

From the mould steel, use which type mould steel is very important.Normally, we use P20 mould steel and 45 mould base, sometimes 718 mould steel is also used. For mould structure, stripper plate can let crate drop automatic, but cylinders may need hand to take the crate.

Remo Mould Services:

(1).Remo Mould is good at making all kinds of plastic mould.

(2).Send quotation list in time.

(3).Have really senior technical consultant to help solve mold skill issue.

(4).Follow mould making time, will not delay the delivery time.

(5).High efficiency, competitive price.

(6).every 5-10 days, Remo Mould will send customer mould machining process by photo or video.

(7).Remo Mould always use good machine to mould processing in order to ensure mould quality!

(8).After-sales Services: Experienced engineers will provide all-round technical solutions to any problems occurred in customers' mould operation.

(9).Remo Mould always keep to good quality, sincere attitude,do best jobs. Since Remo Mould knows nobody want to get bad goods after spending money.

Summary:

Mould Description:Plastic Crate Mould

Mould steel:Chinese 45#, Pre-hardened P20, DIN1.2311, 718H,DIN1.2738 mould steel for cavity and core (optional)

Mould base:SC45#, made in China, LKM mould base.

Injection gate:hot runner or cold runner optional.

Hot Runner:Yudo Hot Runner, Moldmaster , Local Hot Runner (optional).

Mould Components:HASCO standard, DME standard.

Ejector style:Stripper Plate

Mould Life:I million shots

Name | Crate mold |

Plastic resin | PP+EPDM |

Mould dimension(mm) | 885 X 705 X 567 |

Manufacture time (day) | 50-60 DAYS |

Mould life (ten thousand) | ≥50 |

Cooling line connector type | DME NS350 SERIES quick coupling, connected to main water manifold by FST100 MS joint connector, excellent cooling system design |